Trustech Introduces Leading Concentric Hollow Fiber Membrane Spinneret For Uniform Fiber Morphology

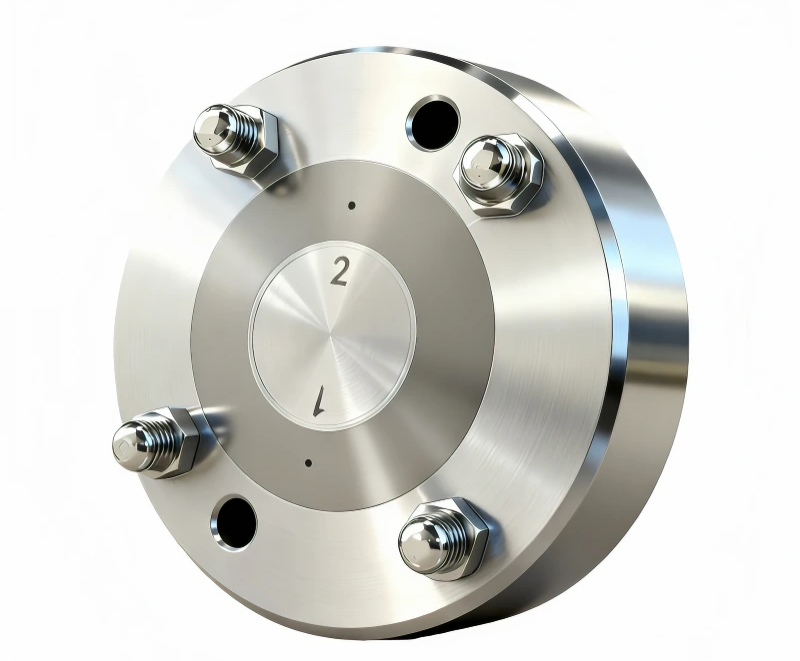

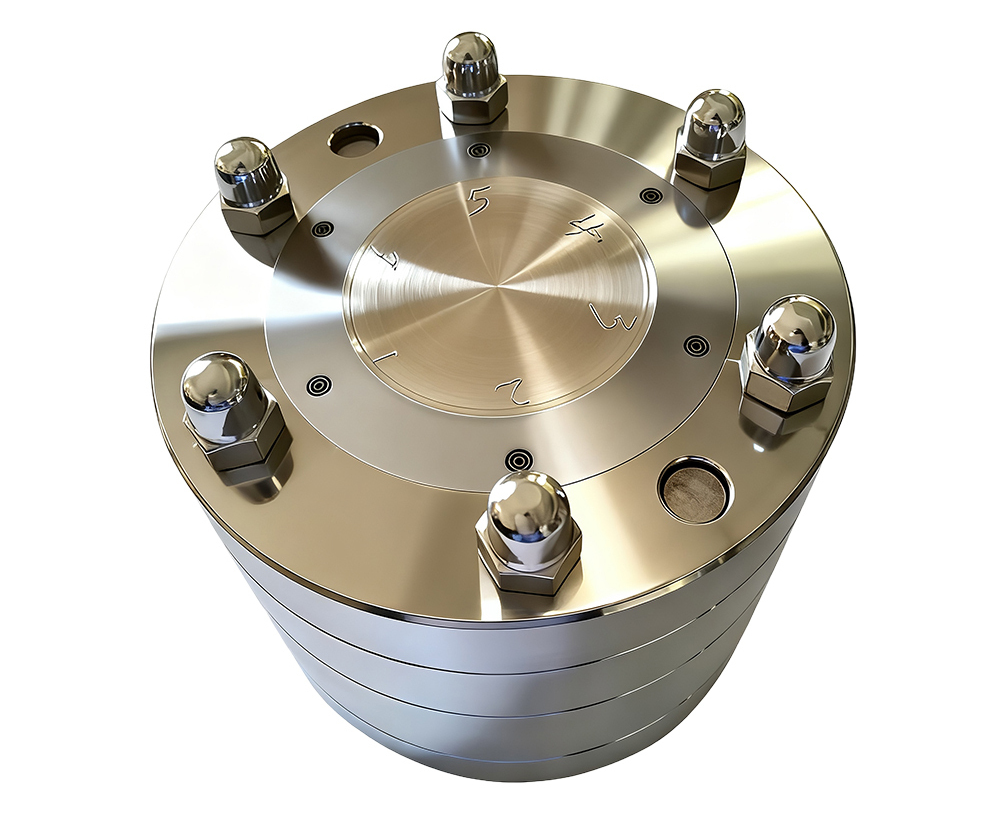

Jiading, Shanghai Jan 4, 2026 (Issuewire.com) - Shanghai Trustech Technology Development Co., Ltd has issued a technical update that highlights the significance of spinneret precision for membrane manufacturing. As a leading enterprise specializing in the research and manufacturing of hollow fiber membrane spinning machines, flat sheet membrane casting machines, and spinnerets for uniform fiber morphologies the company has successfully created the Leading Concentric Hollow Fiber Membrane Spinneret For Uniform Fiber Morphology. This high-precision component serves as the core extrusion tool during spinning process, employing advanced micro deep-hole manufacturing technology for assembly concentricity as low as 0.003 mm. Precision ensures uniform wall thickness and stable fiber diameters during phase inversion, an essential step for creating microfiltration (MF), ultrafiltration (UF), and gas separation membranes. Minimizing fiber eccentricity and structural defects helps support stable flux and rejection performance for demanding healthcare and environmental applications.

Market Development and Trend Analysis for Membranes

Transition towards Automated Fabrication

The international membrane industry is currently experiencing a profound transition, with hollow fiber membrane sales expected to expand significantly before the end of the decade. This rapid global growth could signal that automated fabrication may soon become mainstream within this field. As environmental regulations tighten and resource recovery requirements grow more pressing, manufacturers have increasingly moved away from manual production methods in favor of fully automated high-output spinning lines. Stability in spinning processes--specifically fiber morphology uniformity--is now seen as one of the key indicators of commercial viability of filtration products. Modern industrial requirements call for systems capable of guaranteeing structural integrity over extended 24-hour cycles, as minor variations in fiber dimensions can cause significant failures at large water treatment and desalination plants.

Technological Requirements in Specialized Gas and Medical Separation

Specialized gas and medical separation techniques such as hemodialysis, artificial lungs (ECMO), hydrogen-nitrogen gas separation require precise membrane fabrication techniques with very limited room for error. Market trends indicate a shift toward equipment offering real-time monitoring and outstanding mechanical stability for producing zero defect outputs. As manufacturing shifts towards higher-value technological innovation, its focus has shifted toward localizing complex production capabilities. Modern industrial systems prioritize integrated control interfaces that coordinate material delivery with spinning speed to guarantee that every kilometer of fiber produced meets the stringent safety and purity standards required by pharmaceutical and biotechnology industries.

Sustainability and the Development of Advanced Separation Applications

Global sustainability goals are driving an explosion in hollow fiber membrane usage for carbon capture, biogas upgrade, and decentralized water reclamation applications. Production systems need to accommodate for this shift by being capable of handling multiple advanced polymers including PVDF, PES, and other composite materials - PVDF being one example - which then in turn require innovations that reduce polymer waste while optimizing energy use - innovation which plays an essential part in emerging separation tasks where efficiency directly affects overall sustainability and economic feasibility of processes.

More On Putoutnews ::

- How 3D Measurement Scanners Improve Aerospace Components Accuracy

- Michelle Marie Harrison, PharmD, MBA, MS: Advancing pharmacy excellence at Sheltering Arms Institute with VCU Health.

- China's Top Innovation: Sewer Inspection Robot Revolutionizes Trenchless Asia 2025 with BWELL TECHNOLOGY!

- Top Cambrian Park Realtor Cathy Jackson Strengthens Community Roots Through Oster Elementary Garden Sponsorship

- Introducing Jeffrey Nathaniel Watkins, MD: Expert Physiatrist Advancing Care at Ochsner Health

Key Competencies and Market Leadership of Trustech

Trustechs precision engineering and advanced manufacturing capabilities ensure exceptional manufacturing consistency through automated processing equipment and micro deep-hole technology. As a pioneer in hollow fiber membrane spinning machines and spinneret innovation, Trustech introduced the FCT (Fast Change Technology) spinneret with its 5th-generation platform and has since advanced 6th through 8th generation technologies. As Editor-in-Chief of the Hollow Spinneret standard (T/SHDSGY058-2022), and with equipment covering NIPS (MSCS), TIPS, PTFE, and flat-sheet casting processes, Trustechs sustained innovation has resulted in more than 40 authorized patents. Engineering standards ensure clamping accuracy below 0.002mm and hole concentricity of 0.005mm at an L/D ratio of approximately 10, enabling the production of fibers with superior morphology, surface quality, and structural consistency for high-end global markets. The FCT spinneret further delivers broad viscosity adaptability, high spinning stability, modular and integrated design, robust needle construction, easy maintenance, high reliability, extended service life, and efficient cleaningeffectively reducing filament breakage and supporting stable, high-quality membrane production.

Trustech Is A National High-Tech Enterprise with its own research and development framework focused on membrane formation's thermodynamics and fluid dynamics. The company is the first professional entity in China to perform multiple-hole spinneret structure analysis and fluid simulation, enabling an optimal solution for flow rates and pressure distribution within spinning heads. With more than 41 authorized patents to its name, the company continuously improves its spinning systems to support different manufacturing parameters - including different bore liquids and nitrogen environments - which ensure that every polymer dope meets its phase separation needs optimally. This R&D-driven approach ensures equipment that best suits each phase separation requirement for optimum phase separation results.

Application-Specific Customization and One-Stop Solutions

Trustech stands out with its comprehensive service model that delivers tailored technology solutions based on materials used by its customers. Trustech provides custom machine designs and specialized spinnerets tailored to meet the exacting demands of medical-grade dialysis fibers or industrial-scale desalination membranes, whether for medical dialysis treatment or industrial desalination membrane production. The "one-stop" approach covers every stage of an equipment's lifecycle - from initial fluid simulation and machine design through commissioning, technical support and final technical commissioning. This commitment ensures that production lines are tailored specifically for their intended separation tasks; optimizing flux and rejection efficiency while providing a flexible platform that supports future expansion.

Industrial Impact and Global Reach

Trustech Spinning Systems Are Used Across Critical Medical and Environmental Sectors

Trustech's high-precision spinning systems have found use across an extensive variety of critical application scenarios, from medical imaging to environmental protection. Medical technology is crucial to manufacturing hollow fiber membranes used in hemodialysis and oxygenation (ECMO), where consistency is of utmost importance for survival. Environmental equipment produces fibers for municipal wastewater treatment and industrial effluent purification. Furthermore, the company's technologies enable production of gas separation membranes essential for nitrogen generation and carbon capture - thus supporting global progress toward cleaner energy production and more efficient industrial processes.

International Market Presence and Technical Reliability

Trustech equipment's technial reliability can be seen by its global reach; with customers in 39 countries such as the UK, France, US and Singapore. Trustech holds an AAA-credit rating and membership in Membrane Industry Association of China which shows their stability as an organization that can be relied upon. Trustech boasts an established service network as well as continuous process improvements which support its machinery providing modernization solutions that help manufacturers modernize their filtration and separation facilities according to global standards.

Conclusion: Setting the Standard for Modern Fiber Spinning

A technical analysis of modern membrane fabrication identifies precision and consistency as essential elements of market leadership, and Trustech has successfully integrated them through high-precision engineering and continual research. Providing the Leading Concentric Hollow Fiber Membrane Spinneret For Uniform Fiber Morphology, Trustech remains essential tools needed to advance cleaner water, medical safety, and industrial efficiency worldwide.

As the industry moves toward more automated and sustainable processes, high-precision spinning systems will only become increasingly essential. Trustech remains committed to supporting global membrane industry with infrastructure necessary for producing high performance materials by adhering to rigorous manufacturing excellence standards; by adhering to this approach it hopes to remain at the forefront of separation science for years to come.

For more information regarding technical specifications, product portfolios and corporate developments please visit: https://www.xtrustech.com/

Media Contact

Shanghai Trustech Technology Development Co., Ltd.

Source :Shanghai Trustech Technology Development Co., Ltd.

This article was originally published by IssueWire. Read the original article here.